BLIIOT Smart Boiler Remote Monitoring System RTU Gateway S475

Background

The pressure boiler is a pressure vessel and has the danger of explosion. According to the analysis of boiler explosion cases for many years, the main reason is that the boiler operator did not follow the standard operation and made mistakes; the operator neglected his duty and forgot to add water, resulting in serious dry burning; Severe scale; failure of equipment safety valves, pressure gauges, and overpressure alarm lamps; poor equipment design, structure, and welding.

Program overview

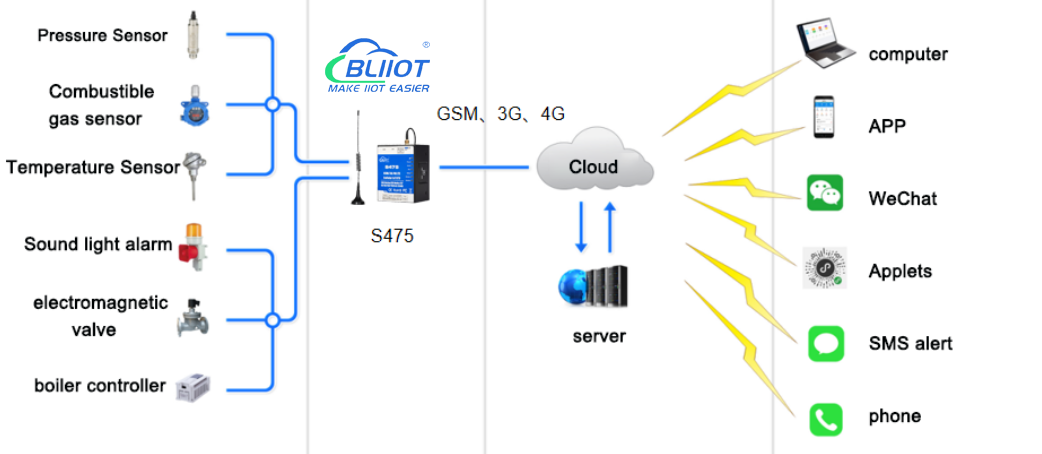

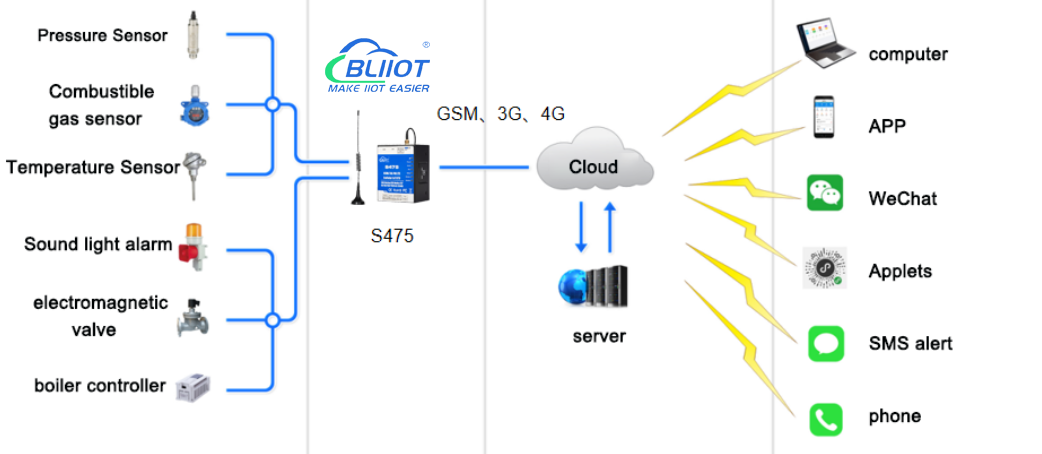

The boiler safety monitoring solution of BLIIOT technology, based on the mature Internet of Things cloud system of BLIIOT, realizes the multi-dimensional monitoring of the boiler and prevents boiler safety accidents caused by human factors; when the pressure in the boiler is abnormal, the cloud platform immediately passes through SMS, phone, WeChat, email and other ways to notify users; when users fail to deal with it in time, task triggers can also be set to link with other devices to deal with abnormal situations in a timely manner.

Features

Device monitoring

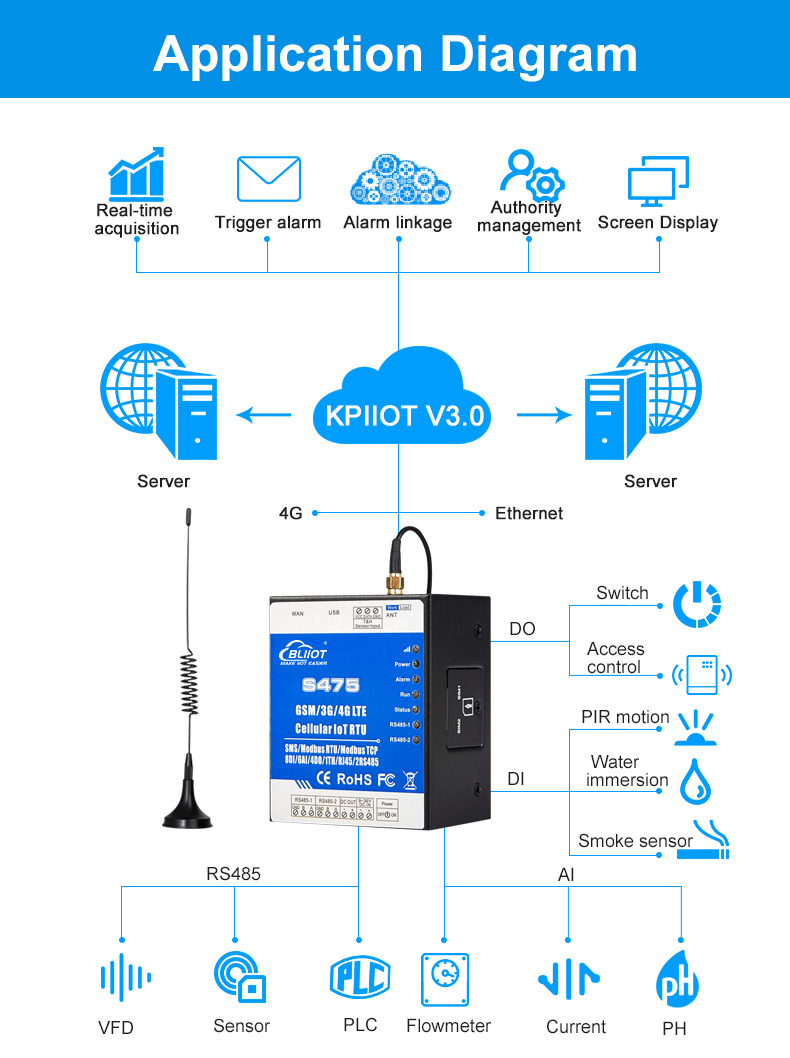

When equipment is connected to the cloud platform, the latest data can be viewed in real time, making real-time monitoring more reassuring.

Remote monitoring

Remotely send commands to control the boiler through the cloud platform, and deal with emergencies in an emergency.

Abnormal alarm

When there is an abnormal situation in the boiler operation, the user can be notified through various channels such as sms,app,wechat,phone call ect.to ensure that the alarm information is delivered in real time.

Data analysis

Combined with the big data of the Internet of Things, it conducts trend analysis and risk early warning assessment for equipment data.

Solution advantage

Solution advantage

1.Support real-time video monitoring.

2.Multi-person notification ensures that the alarm information is delivered on time.

3.Combustible gas detection, immediately alarm in case of gas leakage.

4.Emergency treatment, remote treatment and rapid response in case of emergency,Multi-point monitoring, the same account can monitor multiple devices at the same time.

5.No distance limitation, using mature bliiot cloud platform + 4G transmission global monitoring.

6.Historical record preservation, the platform saves historical data for up to half a year, and supports historical record download and export.

7.Comprehensive monitoring of water temperature, pressure, switch, steam pressure, steam flow, boiler operation and other parameters.

More information about the BLIIoT Smart Boiler Remote Monitoring System RTU Gateway S475: https://www.bliiot.com/remote-terminal-units-p00178p1.html