IoT Applications

Pulse counting serial communication IO module application industrial automation

Views : 8132

Author : Jeakie

Update time : 2023-04-10 16:45:06

Pulse counting serial communication IO module application industrial automation

The pulse counting serial communication IO module is an I/O device used in industrial automation control systems. It can realize the counting and collection of digital pulse signals, and transmit the data to the host computer for processing through serial port communication.

In the process of industrial production, it is often necessary to monitor and count some motion parameters in real time, such as flow monitoring and speed monitoring on the production line. The traditional counting method requires manual operation, which is not only inefficient, but also prone to errors. The pulse counting serial communication IO module realizes automatic counting and collection by digitizing data, which can greatly improve the accuracy and efficiency of counting.

In addition, the pulse counting serial communication IO module also has the advantages of high real-time performance, reliability and scalability, and can adapt to different working environments and application scenarios.

In short, the application of pulse counting serial communication IO modules can play an important role in the field of industrial automation control, improve industrial production efficiency and quality, reduce production costs, and improve enterprise competitiveness.

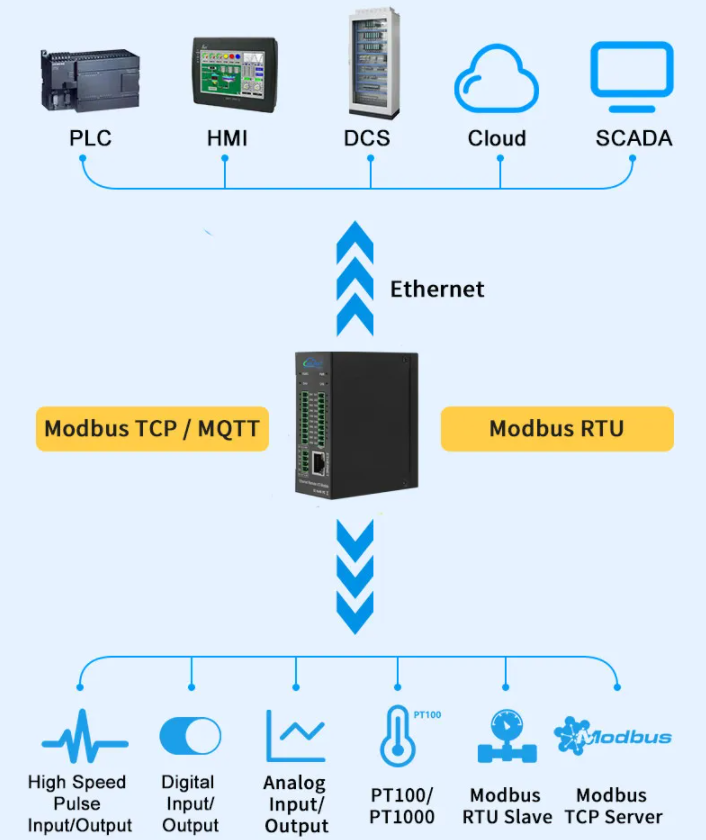

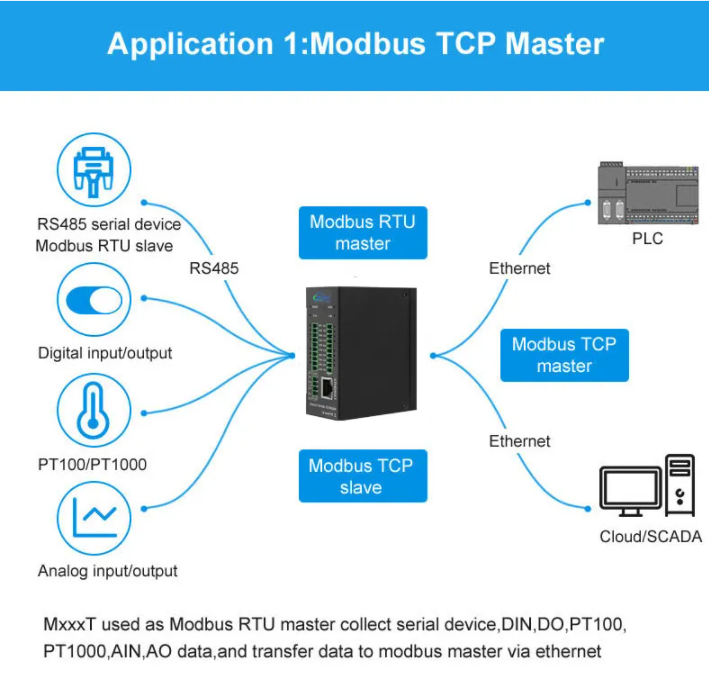

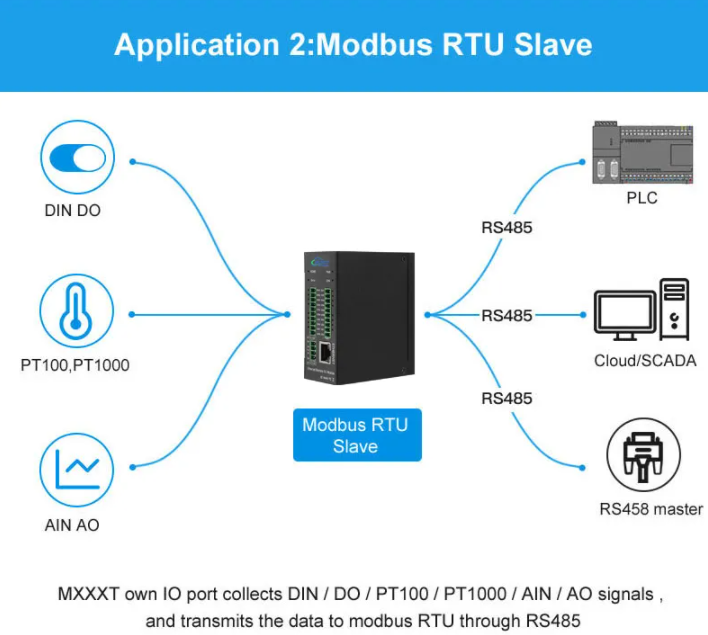

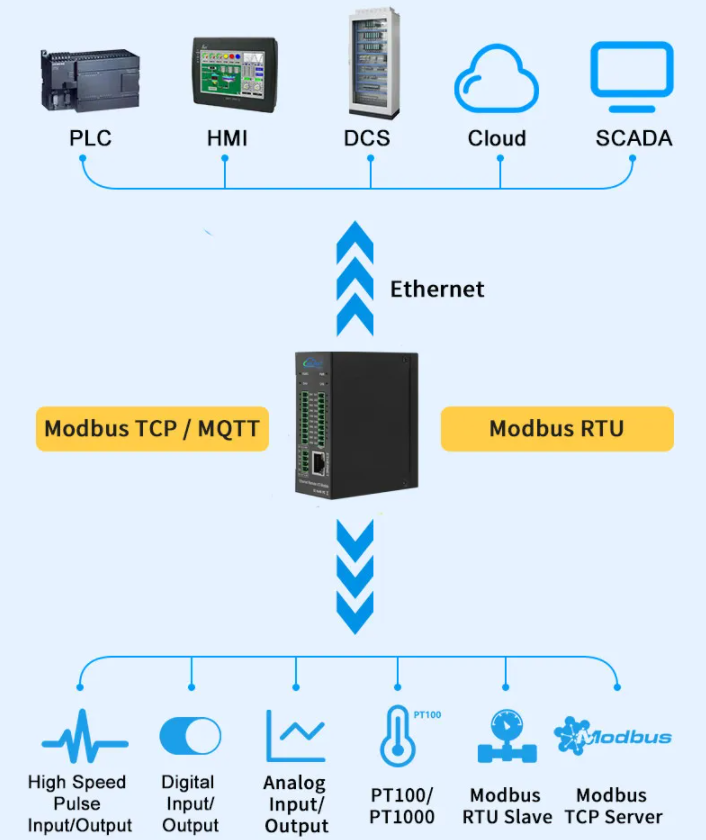

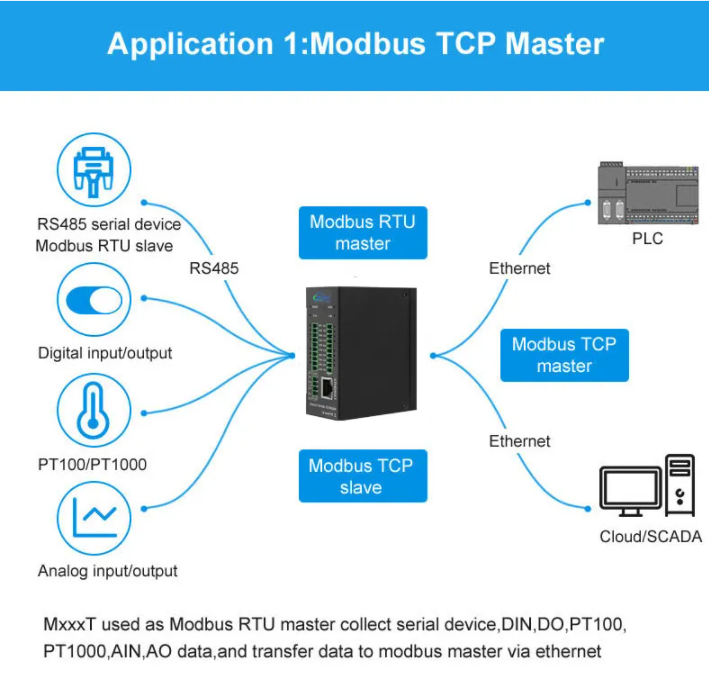

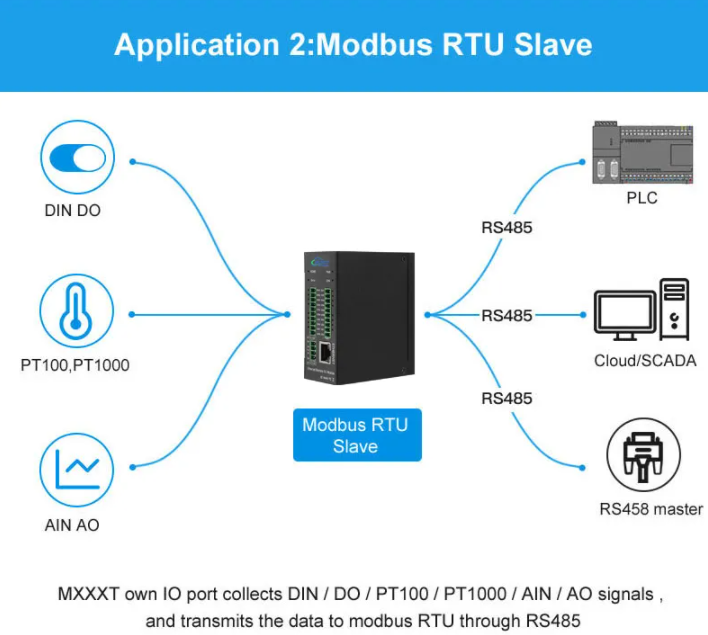

It is worth noting that the application of the pulse counting serial communication IO module can also be used in combination with other sensors and controllers to form a complete automation control system. For example, more complex control functions and monitoring tasks can be realized by connecting with PLC, HMI and other equipment. In addition, the application of this module can also use various industrial communication protocols to realize interconnection with other systems and provide support for the development of emerging fields such as intelligent manufacturing and Industry 4.0.

The pulse counting serial communication IO module is an I/O device used in industrial automation control systems. It can realize the counting and collection of digital pulse signals, and transmit the data to the host computer for processing through serial port communication.

In the process of industrial production, it is often necessary to monitor and count some motion parameters in real time, such as flow monitoring and speed monitoring on the production line. The traditional counting method requires manual operation, which is not only inefficient, but also prone to errors. The pulse counting serial communication IO module realizes automatic counting and collection by digitizing data, which can greatly improve the accuracy and efficiency of counting.

In addition, the pulse counting serial communication IO module also has the advantages of high real-time performance, reliability and scalability, and can adapt to different working environments and application scenarios.

In short, the application of pulse counting serial communication IO modules can play an important role in the field of industrial automation control, improve industrial production efficiency and quality, reduce production costs, and improve enterprise competitiveness.

It is worth noting that the application of the pulse counting serial communication IO module can also be used in combination with other sensors and controllers to form a complete automation control system. For example, more complex control functions and monitoring tasks can be realized by connecting with PLC, HMI and other equipment. In addition, the application of this module can also use various industrial communication protocols to realize interconnection with other systems and provide support for the development of emerging fields such as intelligent manufacturing and Industry 4.0.

Related News

Read More >>